what is a millwright?

As a millwright, you are an industrial jack of all trades due to your knowledge of handling heavy machinery and equipment. Your job involves installing and assembling machinery in power plants, factories and construction sites. To install machinery, you read blueprints and interpret technical specifications.

Aside from assembling equipment, a millwright also performs maintenance and repair tasks in a production facility. When a machinery malfunctions, you diagnose the problem and recommend the repair work required. You move the equipment away from the production for easier dismantling during the repair. After the repair, you test the performance of the equipment to ensure it works efficiently. Your job is to create solid foundations for machines and guide other workers on safety and efficiency in using machinery and equipment. You also recommend work safety requirements to avoid accidents in the factories.

Millwrights are highly skilled and have a good understanding of how equipment or machines work. Your expertise in machine operations makes it easier for you to identify and repair problems in the equipment. You also require manual agility and the ability to use various hand tools like hammers and equipment for welding, cutting and brazing.

Would working as a millwright suit your knowledge of machinery? Then read on to find out what competencies and qualifications you need to thrive in a millwright role.

millwright jobsaverage millwright salary

According to Job Bank, the average salary of a millwright in Canada is $66,300 annually. The hourly rates average $34. The earnings of millwrights depend on experience, educational qualifications and location. When you work in an entry-level position, your salary starts at $58,500 per year. As your experience and knowledge in the industry improve, your take-home salary also increases, and you can earn over $78,000 yearly. Some regions in Canada pay higher salaries due to the demand for the role. For instance, if you work in the Northwest Territories, you receive an average salary of $80,653 annually. Working in British Columbia attracts a salary of $ 77,631 per year, while in Alberta, the salary is $77,211 yearly.

how to increase your salary as a millwright

Millwrights’ salaries depend on their responsibilities and the industry. You earn a higher salary when you perform complex duties like assembling machinery in a factory. Millwrights with extensive experience can negotiate a higher salary due to their knowledge and expertise. Your qualifications also boost your earning potential.

The size of the company also influences your earnings. In a large organization, you earn more due to the complexity of your duties. Besides, a large company has unlimited resources and can afford higher salaries.

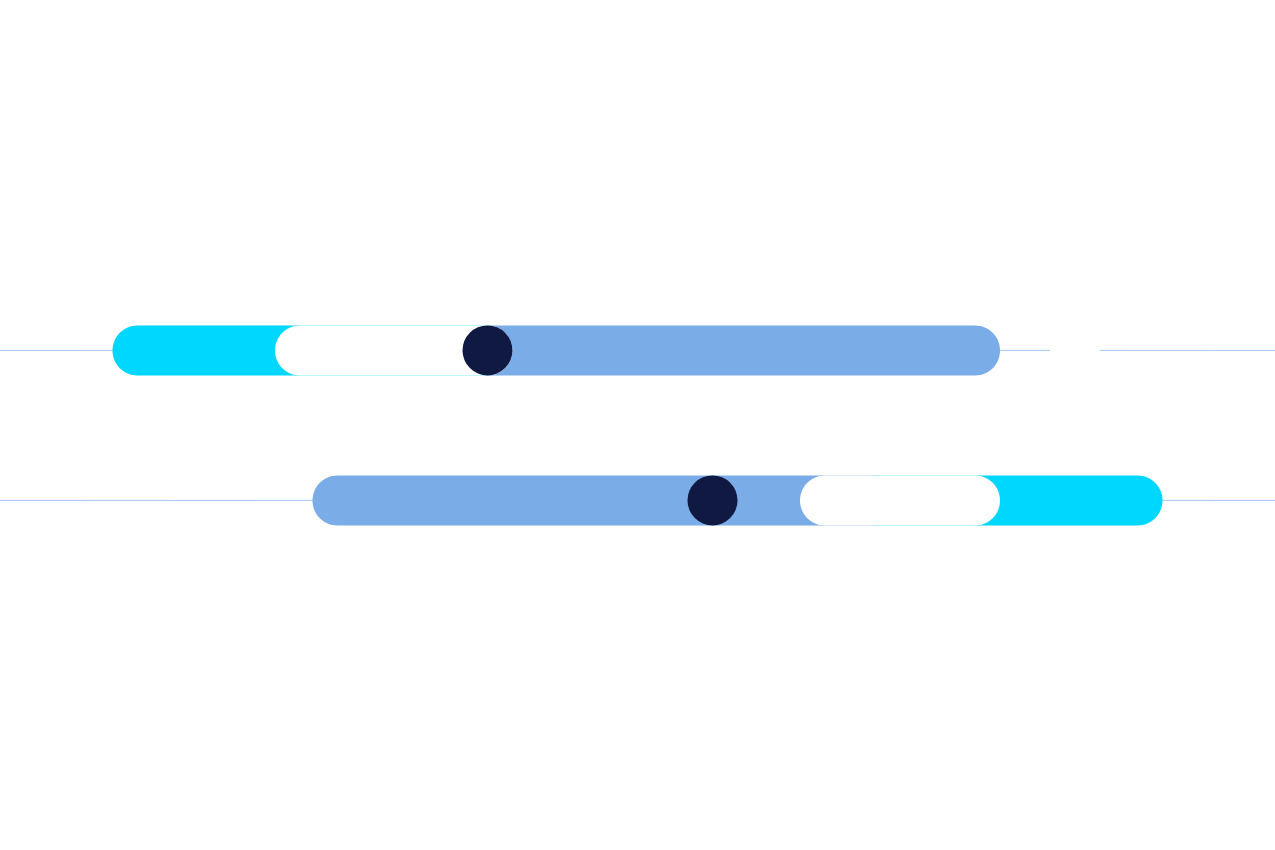

compare your salary now!

See how your pay stacks up against the average by job title and location.

access our tooltypes of millwrights

Millwrights specialize in various industries. Some of the types of millwrights include:

- industrial mechanic millwrights: as a millwright, you work on industrial machinery and equipment. Your job is to fix problems related to mechanical equipment and components in industrial settings. For instance, you assemble and calibrate production machines to ensure they work as expected.

- construction millwrights: as a construction millwright, you specialize in assembling and installing machinery on construction sites. You also dismantle the machines when the construction project is done and prepare them for transport to another site.

working as a millwright

Working as a millwright requires expertise in machinery and heavy equipment. Some of the millwrights' duties, tasks and work environments are explained below.

-

what does a millwright do?

Millwrights typically perform the following duties:

- reading blueprints and plans: as a millwright, you determine the right position to set up heavy industrial equipment and machinery. Hence, you participate in the layout and placement of industrial machines in machine shops, manufacturing plants and fabrication shops. Your job is to analyze the layout plans and schematics before installation. You also ensure the area is ready for the installation of heavy machinery.

- installing and assembling machinery: as a millwright, you require extensive knowledge in assembling machine parts and reading technical instructions and engineering specifications. During installation, you rely on hand and power tools to assemble the parts. Sometimes, you adjust and align the moving parts to ensure they fit perfectly. You also test the newly installed equipment or machines to ensure they work correctly. Other duties during assembling includes calibrating, levelling and lubricating machinery.

- dismantling and moving machinery: when the company is replacing old machinery, you take apart the equipment and clear the area for new machines. You disassemble and move the machines and sometimes reassemble them in different locations. When a construction project ends, you dismantle and prepare the machines for transport.

- troubleshooting and repairing machines: as a millwright, you diagnose problems in heavy equipment and devise troubleshooting solutions. You perform the necessary repairs to minimize downtimes and ensure efficient operations. After identifying issues, you order new parts to replace the damaged ones and run tests to check if the issue is resolved.

- performing routine maintenance: as a millwright, you are expected to perform preventive maintenance. You regularly check machines and equipment to identify potential issues and recommend repairs. You also maintain updated maintenance logs and make adjustments to the calibrations.

-

work environment of a millwright

Millwrights work in the construction and manufacturing industries. Hence, the work environment depends on the industry you work in. For instance, when you work in the construction industry, your work environment is the construction site. That involves working in awkward positions like on top of ladders or in cramped conditions. Millwrights are subject to injuries, such as bruises, cuts and strains, due to the hand tools they use. Hence, you are expected to wear safety equipment like earplugs, safety glasses, hard hats and steel-toed shoes. In manufacturing, you work indoors in factory settings, where the temperature is climate-controlled to suit the production activities.

-

who are your colleagues?

As a millwright, you have diverse colleagues depending on the industry. In construction, you work in close proximity to construction managers, general labourers and mechanical engineers. You also work alongside project managers and carpenters. In manufacturing, you are likely to work with maintenance technicians, maintenance engineers and factory supervisors.

-

millwright work schedule

As a millwright, you work the traditional business hours in a full-time position. Some construction companies expect you to start working early to check the machinery before construction begins. You also perform repairs and maintenance at the end of the construction work. When you work in a factory that runs 24 hours daily, you work in shifts to ensure the construction work is always monitored.

-

career opportunities as a millwright

Millwrights are in demand in construction industries and factories. You can specialize in working in the construction industry or factories. You start as an apprentice and improve your skills to become a journeyman. With your knowledge working as a millwright, you perform various duties associated with welding and pipefitting. That means you have a chance to become a pipefitter or welder.

-

advantages of finding a job as a millwright through randstad

Working with Randstad offers you a range of benefits.

- always a contact person you can fall back on and ask for help from

- many training opportunities

- a range of jobs in your area

millwright skills and education

Some of the requirements to become a millwright include:

- apprenticeship programs: to become a millwright, complete secondary school and pursue training courses or vocational programs. Millwrights are expected to complete a three to four-year apprenticeship program. The apprenticeship requirements for millwrights include 1,560 hours of on-the-job training annually. When you complete your apprenticeship, do an interprovincial exam, and if you excel, you will receive a Red Seal. Completing the apprenticeship program earns you a journeyperson certificate and an advanced diploma.

- experience and certification: you require extensive work experience as a millwright. Since being a millwright is a regulated trade in Canada, you should fulfil the requirements for eligibility for trade certification. For instance, in British Columbia, you require a certification from the Industrial Training Authority of British Columbia. In Saskatchewan, millwrights are regulated by the Saskatchewan Apprenticeship and Trade Certification Commission. You should check the relevant authority in your state or territory to ensure you have the necessary certification.

competencies and characteristics of millwrights

Some of the qualities of millwrights include:

- mechanical skills: as a millwright, you work with machinery and heavy equipment. You require extensive knowledge of mechanical parts like hydraulics, motors and belt systems. Your expertise in welding and fabrication is also important when assembling the machine parts.

- physical capabilities: as a millwright, you use various hand tools to dismantle or assemble machine parts; your physical skills are important. You require good hand-eye coordination for flexibility in using hand tools.

- mathematical skills: as a millwright, you rely on measuring and making calculations when calibrating the machinery. Your math skills help you assemble the machine parts correctly and ensure they work as expected.

- team skills: as a millwright, you work with various professionals, including engineers and plant managers. Your team skill helps you collaborate well with others.

FAQs

Here, you will find the answers to the most frequently asked questions about the profession of a millwright.

-

what are the main duties of a millwright?

As a millwright, you assemble and install equipment and machinery. You read and interpret blueprints and schematics before the installation process begins. You also put together equipment and test its functionality during installation. That means you align and calibrate machinery to ensure efficient and safe operations. You dismantle machines and move them to the repair site during repairs to avoid contamination or workplace safety hazards.

-

is millwright a good career?

Working as a millwright is a great career. Millwrights are always in high demand due to their knowledge of the mechanical field and flexibility of skill. You can work in various industries since you assemble and install diverse equipment. The ongoing need to service and maintain equipment in various industries also increases the demand for millwrights.

-

what are the top skills of a millwright?

Becoming a millwright in Canada requires knowledge of some specific skills. For instance, you require expertise in industrial machines to understand blueprints and technical drawings. You also need attention to detail to correctly calibrate the mechanical parts. Since you repair machinery, analytical and problem-solving skills are useful in diagnosing issues in equipment and resolving the problems.

-

is a millwright a mechanic?

As a millwright, you install, repair and maintain machines and equipment in factories and production facilities. Hence, a millwright is essentially an industrial mechanic that reads and interprets blueprints before assembling equipment.

-

is a millwright a welder?

A millwright is not a welder, but some of the duties of millwrights involve utilizing welding and metal-shaping processes during installation or assembling machines. Other similar duties to a welder include interpreting drawings and assembling parts. Hence, as a millwright, you can be cross-trained in a second trade as a welder, pipefitter or machinist.

-

how do I find a job as a millwright?

Finding a job near you as a millwright is easy. Search our job offers. Have you found what you're looking for? Then submit your application using the ‘Apply’ button top right on the page. No jobs available right now? Send us your resume and we'll pass it on to a recruiter who will contact you if an opportunity opens up for you.

meet a recruiter

Make sure your resume is up-to-date, including information about your technical skills and certifications. Then share it with us to connect with a recruiter and be matched with job opportunities.